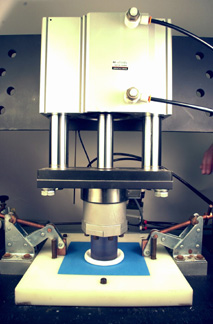

Squeeze Flow Rheometer:

MP&R's squeeze flow rheometer was designed and built especially for the characterization of

various complex fluids, including highly filled materials used in many industries.

The unit is comprised of a pneumatic cylinder, load

cell, LVDT (linear variable differential transformer), thermocouple

and host computer. As the pneumatic cylinder is energized by a command

from the host computer, the ram head moves downward and squeezes a

disk shaped specimen of material. During the squeeze the load cell

measures the reaction force of the material against the ram head while

the LVDT keeps track of the ram position as a function of time. A

thin gauge thermocouple is inserted into the radial surface of the

sample to measure temperature.

When the sample is fully squeezed within a minute

the experiment is complete. The data collected is then fitted to a

mathematical model and the system instantly outputs parameters of

the shear viscosity material function, including characteristic “power

law “parameters. A unique feature of this system is that the

host computer is an embedded PC. This embedded system is comprised

of a number of card modules that are stacked together to achieve the

desired functionality. The embedded PC does not contain any moving

parts and is thus largely maintenance free. The operating system,

source code, and analysis program all reside on one of the card modules.

Data may either be written to one of the modules or to a PCMCIA flash

card, which can be removed from the system with ease. A touch screen

and Visual Basic interface are used for convenient control of the

squeeze flow unit.

MP&R also has available an explosion-proof version of the squeeze

flow rheometer, especially suitable for the energetics industry.

The operator interface of the explosion-proof version consist of an intrinsically safe LCD

display and three logic buttons for control. Historically, to test the consistency

of propellants during a batch mixing process, the operator would remove a small

sample of material from the batch mixer. The operator would then work the material back

and forth between his or her fingers (small amplitude oscillatory shear) and determine

if the batch needed more solvent or if it should be mixed longer etc.

The squeeze flow rheometer solves such quality control problems by giving the operator

quantitative information to work with which can also be monitored by the supervisory staff.