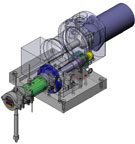

- Use for twin screw testing, sample production, research, instruction and training.

- Realistic and scaleable co-rotating twin screw operation.

- Low volume materials requirements - 50 to 200 gr/hr.

- Fully configured co-rotating twin screw - many screw geometries and materials of construction available.

- Control system - wireless../internet/..remote.

- Barrel and die are jacketed for thermal process conditioning [heating or cooling].

- Multiple solids feed ports, liquid injection port and vent/vacuum port.

- Variable speed hydrostatic drive system, remotely located hydraulic power unit - power requirement of 110 volts.

- Quick open, easily cleaned and disassembled.

- Portable-can be placed in hood - weighs about 40 lbs.-ex remote hydraulic power unit

- Multiple extrusion die configurations available.

- Available auxiliaries:

Micro solids & liquid feeders

Mini vacuum systems

Mini heating and/or cooling units

Grinders / Chill rolls / Pelletizer

|

|

||

|

|

Related Links |

|

|

Products & Solutions | Our Commitment | Our Company Copyright MPR 2004 Have not found what you are looking for? Contact us for more information. |

||